1 name and classification

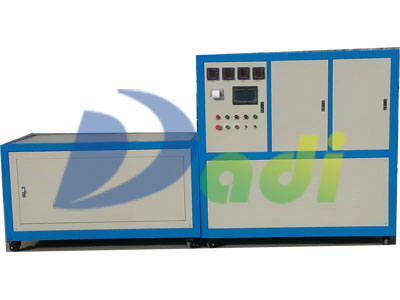

(1) Name: SDDL-5000III large current generator.

(2) the environmental groups: belong to GB6587.1-86 "electronic measuring instruments environmental tests program" in group III instrument (can) for use in an outdoor environment.

2.1 input voltage: 380/220V 50Hz AC three-phase four wire

2.2 power: 1*3 30KVA only 3 phase 30KVA a group

2.3 output current: AC0 ~ 5000IIIA stepless adjustable, panel with digital display current meter

2.4 output voltage: (>6V)

2.5 output waveform: the output current is the standard sine wave, the burr is small, is better than the power system requirements index standard, the ripple coefficient is less than 0.3%. Standard sine wave.

2.6 measurement accuracy: (using the 0.2S material) is actually around 0.3, the current can be smooth and smooth continuous adjustment, the accuracy is higher than 0.5. The current and voltage meter shows the true effective value, high precision, high stability.

2.7 output current mode: the true and effective value can be adjusted continuously;

2.8 current stability: 0.2%

2.9 structural forms: one

2.10 connection mode: according to the requirements

2.11 current stability: 0.2%;

2.12 protection settings: over current, over voltage

Automatic temperature rise special high current generator using low power consumption and high capacity of the pressure regulating device and high permeability core manufacturing converter, and has the advantages of high output power, small volume, light weight, etc.. Mainly used for thermal relay, motor protector, contactors, breaker device, air switch, switch cabinet, circuit breaker, protection screen check busbar, cable, etc.

New features

1, including power to adjust the pressure switch input device, voltage is output to the up flow switch input device, namely before the class, after level; after the corresponding fractions, before class; emergency stop; mutual locking (of substandard, after level does not close; after grade not, before the class not!)

2, with voltage regulator zero lock function;

3, the mutual inductor is provided with two open circuit overvoltage protection, which can avoid the signal line breaking and the current transformer two open circuit to generate high voltage;

4, up flow device body is a hole in the center of large current output can be used directly and conveniently through the conductor, sample any experiment

5, the use of special structure can effectively control the flow of the main bracket of the lifting device, the eddy current heating of the metal;

6, l surface flow device body is arranged on the outer shell of the 4 rings, convenient lifting, is arranged at the bottom of the wheel, easy to move;

Part 7, wireless control, comprises before class, after class, up flow and down flow, after class, before class, emergency stop button, control cabinet latching requirements (of substandard, after level does not close; after grade not, before the class not!) All the control system can be realized on the remote controller, and the wireless control part is embedded in the voltage and current integrated control panel display;

8, wireless control power supply using 5 battery power supply, convenient and quick change;

9, with the current source waveform monitoring Q9 head, to facilitate the monitoring of large current output waveform (can be installed oscilloscope);

10, instrument selection 160*80 digital tube display, facilitate remote (10m) wireless control of the far view, can simultaneously monitor power supply voltage, current, pressure regulator's output voltage, current, up flow output voltage and current;

11, with power-off protection function, up flow during the test, if all of a sudden loss of power again after restoration (in the control panel on the manual closing air switch is closed), pressure regulating motor automatically reset to zero (with zero instructions). Then you can do before the class, after class, up flow and down flow operation strictly avoid with impact load hold jump higher power;

12, according to the user needs to choose 5.7 inch 15 inch 10 inch screen

2.8 structural forms: one or split

2.9 protection settings: over current, over voltage (primary and over current protection)

2.10: 2 action time test: 0.001~99999.999S

1 full automatic control current increases, decreases

2, 64 temperature inspection can be customized according to the requirements of the temperature range of the test pilot.

1) temperature range: -100 to 1000 DEG C; (standard sensor temperature range: -50-300 DEG C)

2) measurement accuracy: 0 ~ 1000 C: + (read value x 0.5%+1),

-100 ~ 0 C: + (reading value x 0.5%+2);

3) has the function of anti high frequency interference.

Number of temperature signal input channels: up to 8 sets of 8 sets, each (by type) (4)

5) sensor: nickel chromium nickel silicon thermocouple (type K) (type T, J type can be customized).

According to customer needs:

1, automatic and manual operation.

2, online display in the process of test current, voltage, transformer and the tested temperature (more), with tables and curves, and transferred to the other computers in the storage for further analysis, use the archive. Data using Excel spreadsheet format, easy to chart, curve form and data conversion between the text using word format.

3, according to the need to set the test current, the test current is stable and reliable, not affected by the system or outside factors.

4, can be set according to the requirement of the subjects of allowable temperature, system automatically adjusts the maximum current setting, when to test the set temperature display and record the moment of maximum working current, bus at the highest allowable temperature of the maximum working current (or set of temperature under the maximum working current).

5, with the transformer and the current test parts of the current, the lowest temperature and the highest value, with more than the limit value of automatic alarm function. Self protection function of over current, over current, over voltage and short circuit.

6, the same test pieces are automatically repeated large current temperature rise test, set the number of tests, test current, interval time, the current speed, the maximum allowable current duration. Finally, after the test, the device is automatically completed. Cycle test can!

7, before the test, the touch screen can be set to complete all parameters, and strive to operate simple and clear.

8, encountered over flow, over-voltage, short circuit, over temperature, pressure loss, with the necessary protection and sound and light alarm signal. For the test device is not necessary to produce destructive alarm factors, it can be issued sound and light alarm, the operator was informed of the alarm according to the actual situation to judge, to make the appropriate treatment. Within a certain period of time after the alarm, no one knows, the device automatically shut down.

Operation interface:

Five, operation instructions

1) page description

1), enter the system

2), the main menu

3), automatic test interface (according to the set value of the current automatic regulation, and automatic tracking output current is infinitely close to the set value. From press Rev

Start time, to set the output time to stop the output of the output or external temperature detection beyond the set temperature

4), parameter setting

5), manual test (manual adjustment of the current size, does not have the current tracking function). Mainly used for the action time of the overcurrent relay

2) setting current output

In the automatic mode, the current setting value is set according to the required current setting value, the output time is set, and the current output value is adjusted automatically after the setting of the voltage regulator.

3) output time

According to the experiment, the output time of the large current is set, and the time when the instrument is stopped.

4) over current protection

According to the magnitude of the timing trigger current to set the value of the current protection, the timing of the current value of 1.1 times the value of the current protection of the action value. Over current protection, instrument alarm.

3 zero start

In order to protect the tested product, the flow regulator should start from "0A". When the pressure regulator in the zero state, press the "start" button, contactor, instrument output, when the voltage regulator in a non null state instrument according to "closing" button, the equipment can not be closing no output.

4 current loop principle

5, plus temperature control: set a good temperature to reach the temperature of the test point, automatic stop output, can be equipped with thermocouple, thermal resistance, etc..

Current generator with constant current

Current generator with constant current Full automatic temperature rising and large curren

Full automatic temperature rising and large curren Small current generator

Small current generator Large current generator

Large current generator AC / DC current generator

AC / DC current generator Intelligent high current

Intelligent high current Three-phase current generator

Three-phase current generator Intelligent three-phase current

Intelligent three-phase current The three-phase voltage and current source

The three-phase voltage and current source Three frequency generator

Three frequency generator Fault indicator tester

Fault indicator tester Fuse tester

Fuse tester Transformer integrative tester

Transformer integrative tester Thermal relay tester

Thermal relay tester Tester for motor protector

Tester for motor protector Relay protection tester

Relay protection tester High voltage switchgear

High voltage switchgear Low voltage switchgear

Low voltage switchgear AC and DC voltage tester

AC and DC voltage tester DC high voltage generator

DC high voltage generator DC breaker ampere second characteristic test instr

DC breaker ampere second characteristic test instr Power inspection class

Power inspection class